With the development of technology and industrialization, sewing—a craft that dates back to civilization itself—has experienced a significant alteration. Industrial sewing is an industry that creates the thread that holds together the fabric of everyday life. It is a result of the transition from hand to machine, from small-scale workshops to vast factories. In order to better understand the intricate world of industrial sewing, this article will focus on its relevance, definition, and constituent parts.

Defining Industrial Sewing

In its most basic form, sewing is the process of using thread and needle to join two pieces of fabric. However, industrial sewing transcends beyond this rudimentary definition. Industrial sewing refers to the mass production of sewn goods using heavy-duty, highly specialized sewing machines. These machines, designed to operate at a faster pace and endure prolonged use, enable the production of vast quantities of consistently high-quality sewn items.

Industrial sewing caters to various industries, from fashion and apparel, furniture upholstery, to automotive interiors, tent manufacturing, and even the aerospace industry. Each of these sectors requires specific sewing techniques and machines, all falling under the umbrella of industrial sewing.

The Significance of Industrial Sewing

The importance of industrial sewing cannot be overstated. The garments we wear, the furniture we use, the cars we drive - all involve a component of industrial sewing.

- Mass Production: Industrial sewing allows for the production of large quantities of sewn goods at an unprecedented speed, fulfilling global demands. Without it, meeting the volume needed for our day-to-day commodities would be an insurmountable task.

- Consistency and Quality: Advanced sewing machines produce consistent, high-quality results. Every stitch is precise, ensuring that each product, from the first to the thousandth, maintains the same standard of quality.

- Economic Impact: The industrial sewing sector generates numerous jobs, contributing significantly to the global economy. It supports ancillary industries, such as textile production, machine manufacturing, and logistics, fostering a vast interconnected network.

What types of stitches are there?

Industrial sewing applications require a wide range of stitches to accommodate various fabrics, designs, and functional requirements. These stitches play a crucial role in ensuring the durability, strength, and aesthetic appeal of sewn products. Here are a few types of stitches commonly used in industrial sewing:

-

Straight Stitch: The straight stitch is the most basic and commonly used stitch in industrial sewing. It involves a single line of stitching created by the up-and-down motion of the needle. It provides strength and is suitable for most fabrics and general sewing applications. This is most often used when sewing woven fabric together.

-

Lockstitch: the lockstitch is a very common stitch used with industrial sewing machines. This type of stitch is when a sewing machine makes a single stitch, the top and bottom threads lock together. This keeps them secure and "locked" together.

-

Chain Stitch: The chain stitch is formed by a single thread that interloops with itself, creating a chain-like appearance on the underside of the fabric. This stitch is flexible and highly elastic, making it suitable for sewing knitwear, waistbands, and decorative stitching. It is commonly used in the production of t-shirts, sportswear, and hems.

- Zigzag Stitch: The zigzag stitch is characterized by a back-and-forth motion of the needle, creating a zigzag pattern. This stitch is highly versatile and can be adjusted in width and length. It is often used for sewing stretch fabrics, finishing raw edges, and creating decorative effects.

How Can Miller Weldmaster Help?

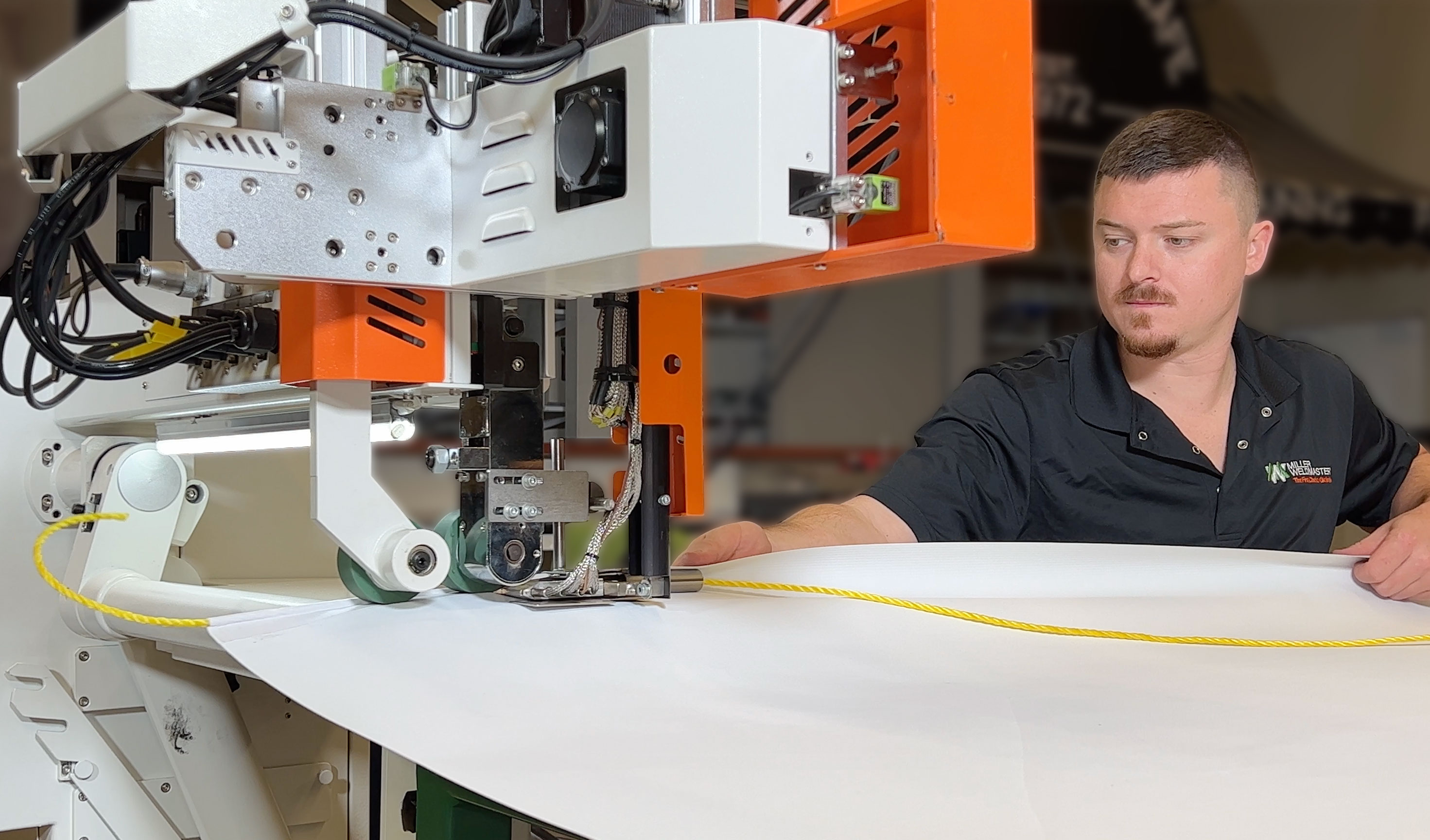

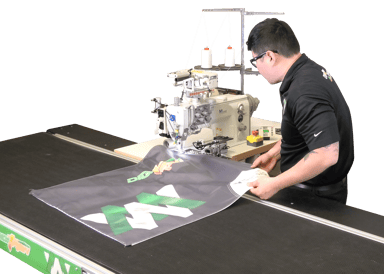

Miller Weldmaster is known for our Hot Air, Hot Wedge, and Radio Frequency welding technologies. The combining of two, thermoplastic materials together using heat, speed, and pressure. But, we also offer a variety of sewing solutions as well! Depending on the material, application, or both welding may not be the best way to produce your products.

Some of the most common sewing applications include filters, Cured In Place Pipeline (CIPP), as well as Signs and SEGs. Our industrial sewing machines vary from heavy-duty automatic sewing machines, where you can incorporate a sewing function into a large unit that welds, rewinds, unwinds, ext. Our standard solution for the sign industry is the Digitran. There are various applications that utilize sewing in their process, and Miller Weldmaster has the solutions and options available to meet those needs.

Industrial sewing is a fascinating combination of traditional craftsmanship and modern technology. It is an industry that weaves our world together, ensuring access to essential products, from clothing to furniture. As technology continues to evolve, the landscape of industrial sewing promises exciting innovation and development, ensuring it remains a crucial part of our industrial framework for years to come.

If you are interested in learning more about Industrial Sewing, check out our YouTube channel, or contact our team of experts today!