- OUR MACHINES

- INDUSTRIES SERVED

- Awning, Shade & Marine

- Cured In Place Pipeline

- Ducting, Ventilation & Hose

- Filtration Tube & Bags

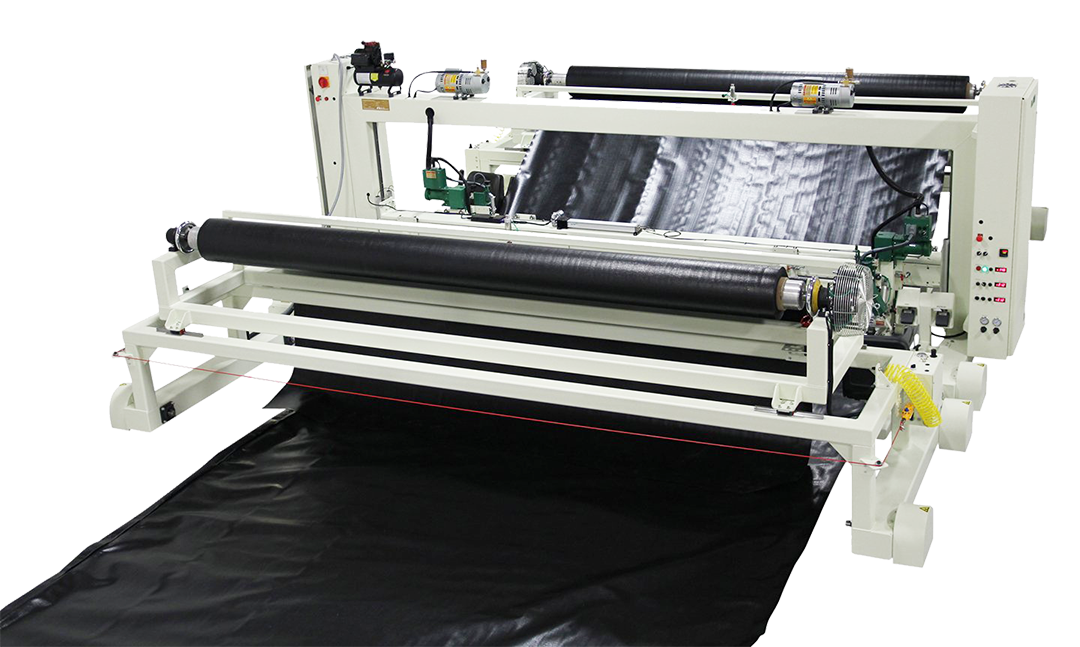

- Geomembrane Liners & Covers

- Inflatables

- Packaging & Sealing

- Pool Cover & Liners

- Roofing Welder Equipment

- Sign Finishing & Banners

- Tarpaulin & Tarps

- Tents, Shelters & Structures

- Sealing Animal Feed Bags

- Organic and Inorganic Fertilizer Packaging Bags

- Other Industries

- TECHNOLOGIES

- SERVICE & RESOURCES

- ABOUT US

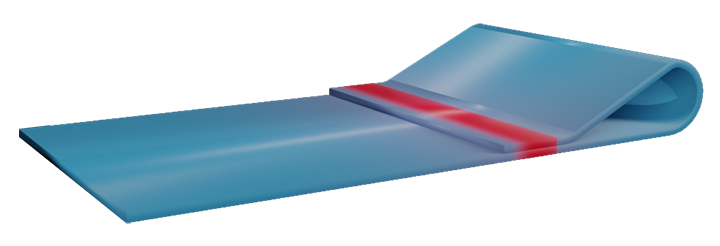

Fold Overlap

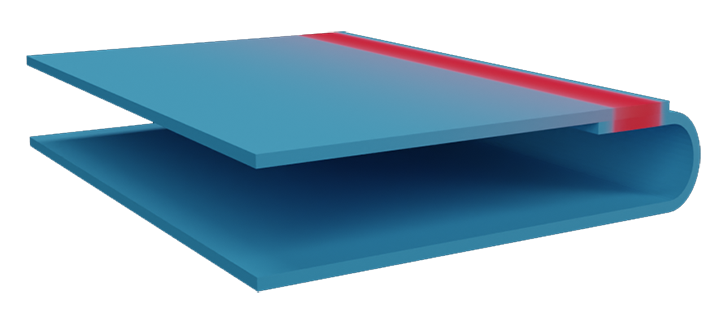

Fold Overlap  Hem with Pocket

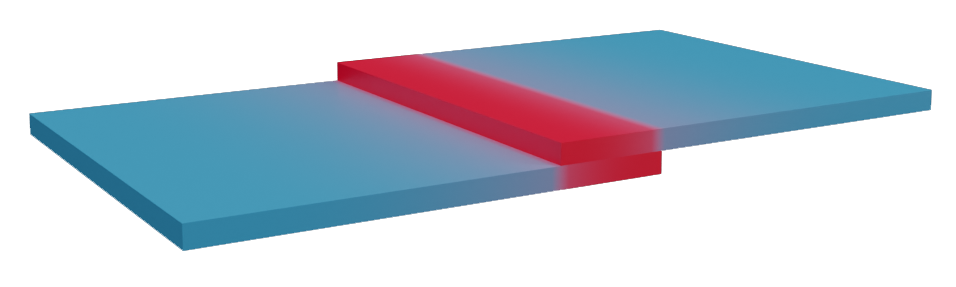

Hem with Pocket  Overlap

Overlap