Find the Perfect Fabric Welding Machine for Your Industrial Needs

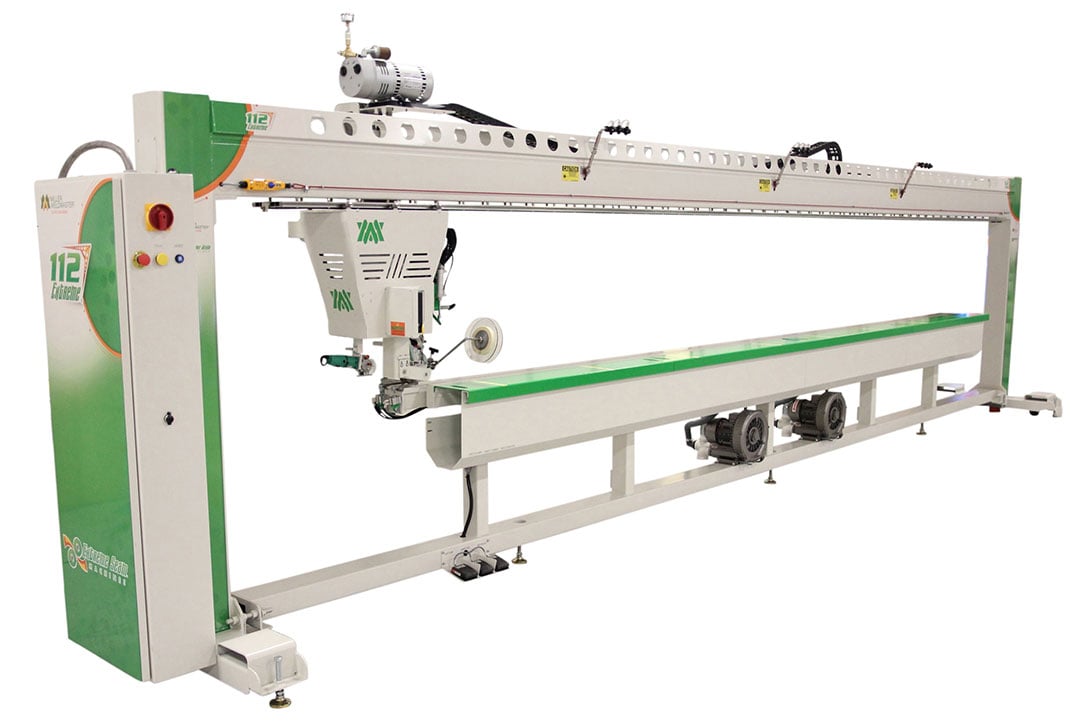

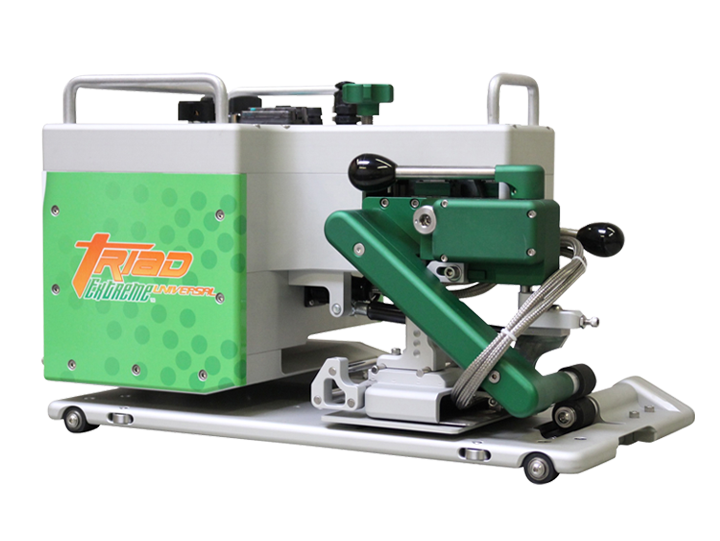

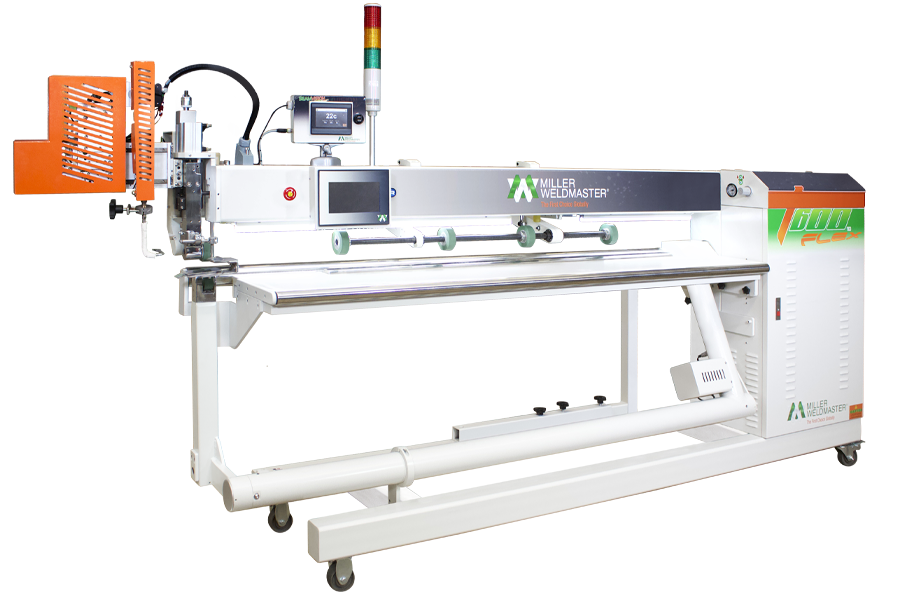

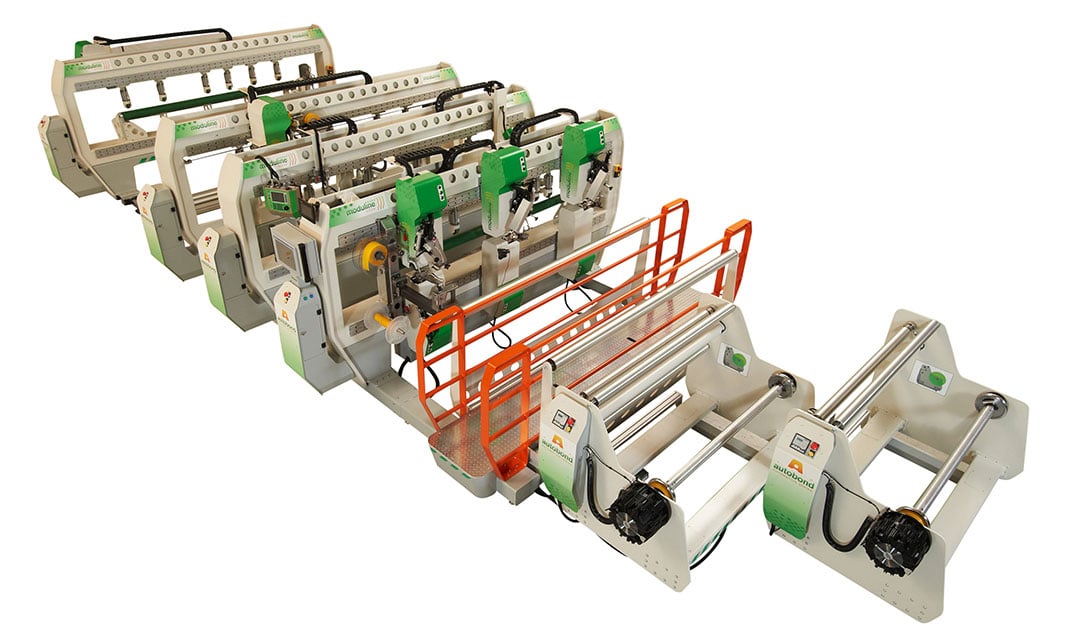

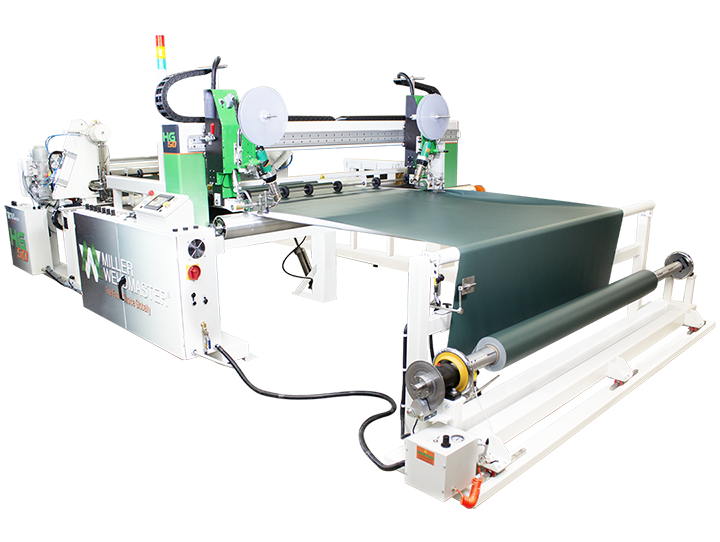

Discover the finest solution for your textile welding requirements with our fabric welding machines. From portable to fully automated industrial fabric welding machines, we at Miller Weldmaster have the perfect equipment to meet and exceed your expectations. Our lineup includes hot air welding machines and hot air welding tools, specifically designed for industrial fabrics and applications such as tarpaulins, banners, and marquees, capable of handling heavy fabric rolls and welding at high speeds with wide seams.

Our fabric welding machines deliver high performance and easy operation, offering you versatility and precision like no other. Built with advanced technology, these hot air welding, hot wedge welding, and radio frequency machines handle fabric seals swiftly and efficiently. This means a considerable reduction in time and money spent, boosting your productivity. They are also adept at working with PVC-coated materials, ensuring compatibility and seamless operation across a wide range of applications. Our machines can effectively close and weld the sides of hem pockets, showcasing their versatility in working with various textiles and reinforcing materials.

Whether you’re in the business of manufacturing tensile structures, pool liners, high-speed rolling doors, oil booms, or billboards, our fabric welding machines are designed to handle a broad array of applications. With their ability to create strong and airtight seams, our machines stand as the preferred choice in the textile industry. Incorporating ultrasonic technology and ultrasonic welding, our machines offer superior weld strength and integrity for non-woven materials across various industries, including medical, hygiene, construction, and automotive.

Furthermore, our fabric welding machines offer considerable adaptability. They can handle a range of materials, including but not limited to PVC and polyurethanes. Our RF fabric welding machines can even weld the same area more than once without damaging the fabric. This adaptability extends to their integration into production lines.

If you’re unsure of which fabric welding machine to choose for your application, our team at Miller Weldmaster is here to assist. We’ll help you select the best technology that aligns with your specific application, ensuring optimal results every time.

Explore our complete range of fabric welding machines. Make the smart choice and invest in a fabric welding machine from Miller Weldmaster today, for precision, efficiency, and cost-effectiveness.

Fabric Welding Machines for Various Industries

Miller Weldmaster offers cutting-edge fabric welding machines crafted to serve the needs of various industries. Whether you are manufacturing tarps and canopies that require durability and weather resistance or working with non-woven fabrics for specialized applications, our solutions are tailored to meet your demands. Additionally, for products that depend on ultrasonic welding technology, our machines ensure sealed seams that are both strong and precise.

For example, in the tarp and canopy industry, our machines create high-quality seams that withstand harsh environmental conditions. In applications involving non-woven fabrics, such as medical or automotive products, our machines deliver dependable results with materials that require delicate handling. For industries relying on ultrasonic welding, such as filtration or packaging, our technology ensures perfect, airtight seams without compromising the integrity of the material.

Hot Air, Hot Wedge, and RF Welding Technologies

At Miller Weldmaster, we specialize in a range of fabric welding technologies, including hot air, hot wedge, and RF welding, to address a variety of applications and fabric types. Each technology offers unique advantages, ensuring you can select the ideal method for your material and production requirements.

Hot Air, Hot Wedge, and Ultrasonic Welding

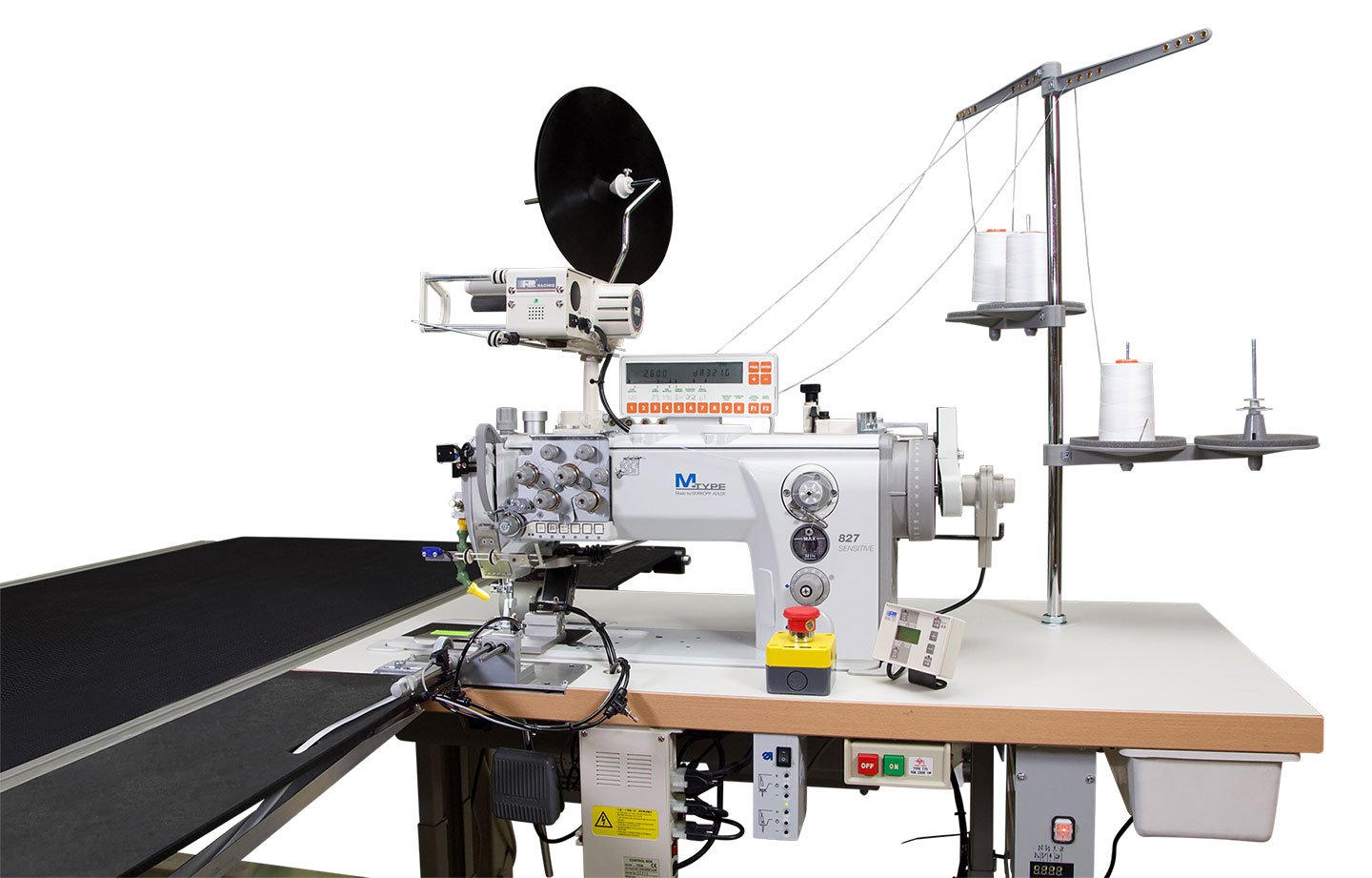

Hot air welding is a versatile method that works seamlessly with materials like PVC-coated and industrial fabrics. This technology is perfect for general use and offers reliable, strong seams. For more delicate materials, such as non-woven fabrics, an ultrasonic welding machine provides precision and airtight results, with programmable functions and versatility in processing materials like filter tubes and various garment types, making it ideal for lightweight and specialty applications. Hot wedge welding is the go-to option for high-volume production, delivering consistent, strong seams for large-scale operations with remarkable efficiency.

RF Welding Technology for Heavy-Duty Fabric Sealing

For heavy-duty applications, RF welding is unparalleled. This method excels in welding thick and robust materials like PVC, creating seams that withstand heavy use and stress. Additionally, RF technology offers a re-weld capability that allows for seamless overlapping without damaging the material, providing flexibility and reliability in production processes.

Fabric Welding Machines for Your Material and Application

Finding the right welding machine for your specific needs has never been easier. Miller Weldmaster designs machines that cater to a wide array of fabric types, from PVC-coated textiles to lightweight non-woven materials. Our team is here to guide you in selecting a solution tailored to your industry and application, ensuring precision, durability, and productivity.

Welding Non-Woven Fabrics and Specialty Textiles

When working with non-woven fabrics and specialty textiles, there are specific considerations to keep in mind. The type of fabric, the required seam strength, and the application’s purpose all play a critical role. For example, ultrasonic welding technology is ideal for non-woven materials in industries like medical and filtration, where precision and airtight seams are essential.

Hot Air, Hot Wedge, and Ultrasonic Welding Machines

Hot air welding provides unparalleled versatility, making it a reliable choice for applications requiring compatibility with multiple fabric types. For applications demanding precision, ultrasonic welding delivers exceptional results for delicate materials. When efficiency and high-volume production are key, hot wedge welding offers consistent and durable performance, ensuring a smooth production process.

Efficient Solutions for Non-Woven and Industrial Fabrics

Miller Weldmaster’s fabric welding machines are engineered to maximize efficiency and productivity. With fast heating times and consistent performance, these machines are perfectly suited for sealing non-woven fabrics and a wide range of industrial fabrics. By reducing downtime and streamlining the welding process, our machines help manufacturers meet tight deadlines and maintain high-quality standards.

Seam Sealing Techniques for Strong and Airtight Results

Our advanced seam sealing techniques ensure results that meet even the most demanding industry standards. For applications requiring waterproof seams, such as outdoor tarps and industrial canopies, our machines deliver exceptional performance. Additionally, the versatility of our solutions ensures compatibility with non-woven fabrics and other industrial-grade materials, providing dependable results across diverse applications.

Benefits of Miller Weldmaster's Fabric Welding Machines

Miller Weldmaster’s range of fabric welding machines offers transformative benefits for your production processes. Our innovative solutions are designed to increase productivity, minimize downtime, and produce high-quality seams tailored to various industries. Whether you’re working with delicate non-woven fabrics or robust PVC-coated materials, our machines are equipped to handle the task with precision and reliability.

Boost Productivity with Seamless Fabric Welding and Reduced Heating Time

Our welding machines are engineered to help manufacturers achieve faster production cycles. With efficient heating times and seamless operation, you’ll experience reduced downtime and increased throughput. Whether you’re working with non-woven materials for medical or filtration applications or creating durable seams for industrial-grade textiles, Miller Weldmaster’s machines deliver the performance and consistency you need to succeed.

Discover how Miller Weldmaster’s innovative welding technologies can revolutionize your production processes. Contact us today to explore our range of fabric welding machines and find the perfect solution for your business.