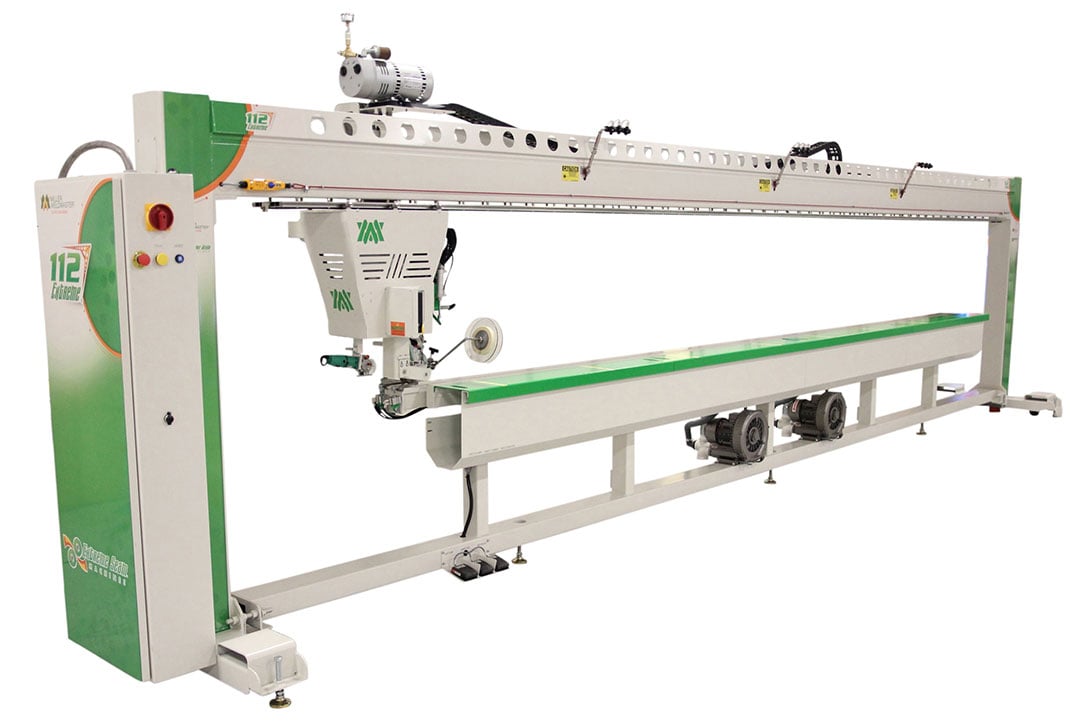

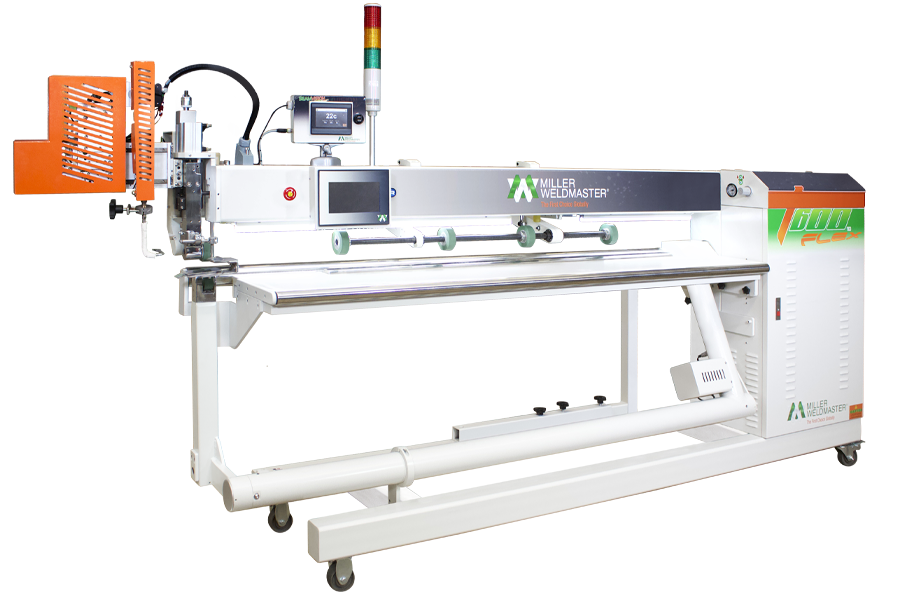

Discover the finest solution for your textile welding requirements with our fabric welding machines. From portable to fully automated industrial fabric welding machines, we at Miller Weldmaster have the perfect equipment to meet and exceed your expectations.

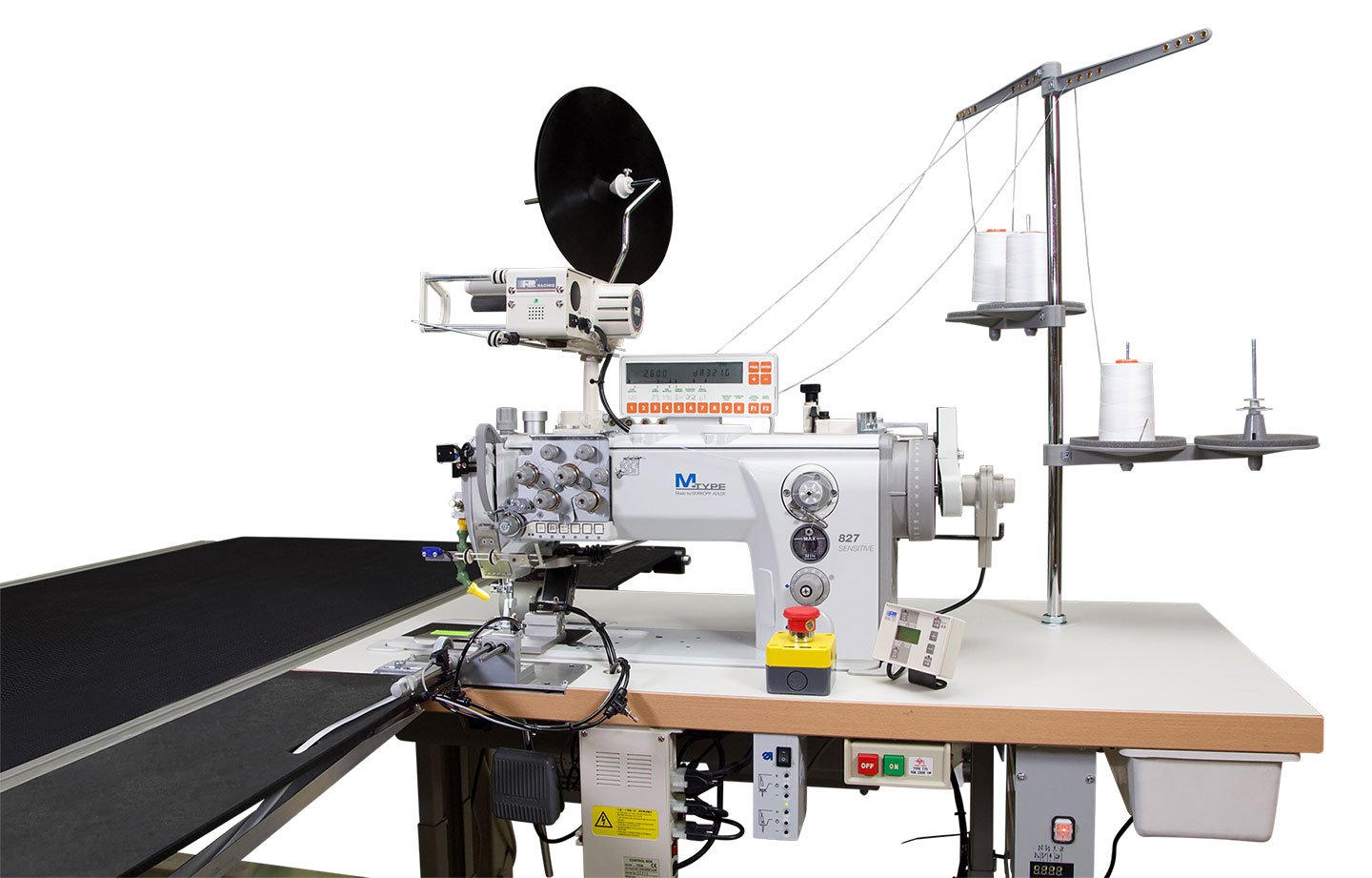

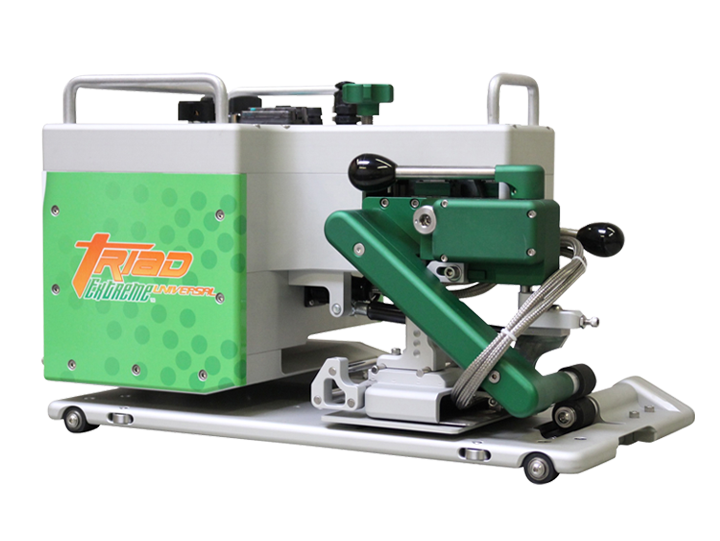

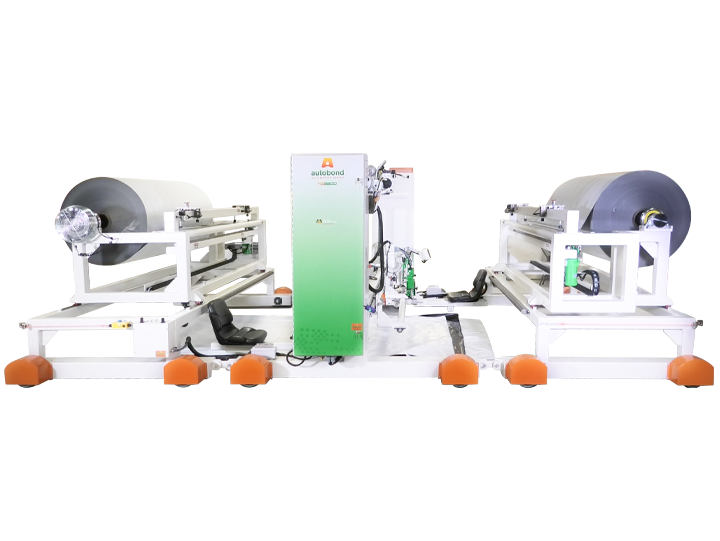

Our fabric welding machines deliver high performance and easy operation, offering you versatility and precision like no other. Built with advanced technology, these hot air welding, hot wedge welding, and radio frequency machines handle fabric seals swiftly and efficiently. This means a considerable reduction in time and money spent, boosting your productivity.

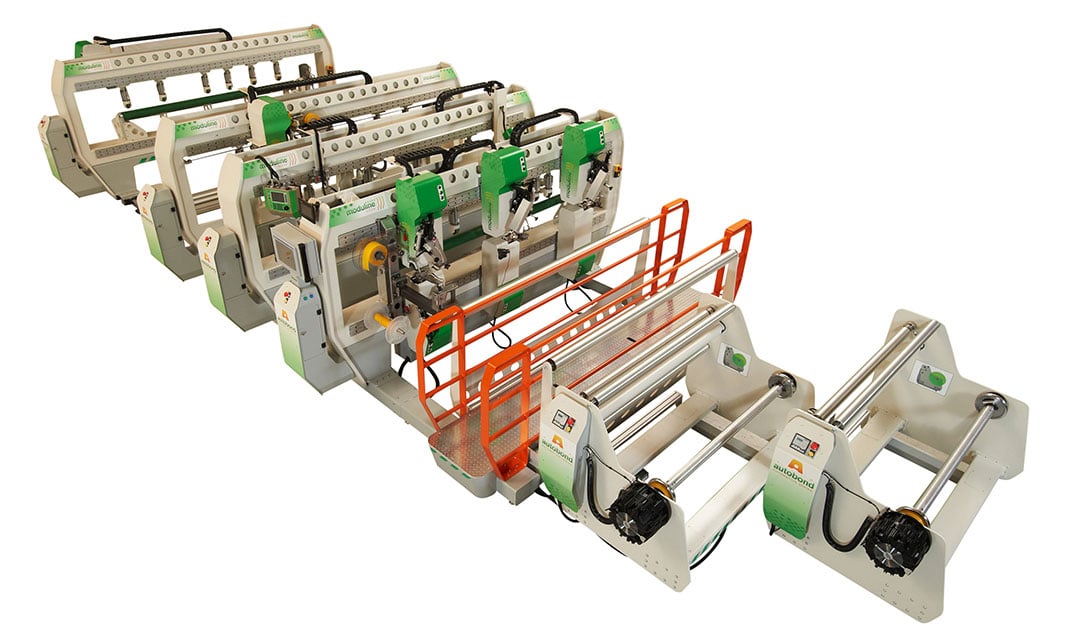

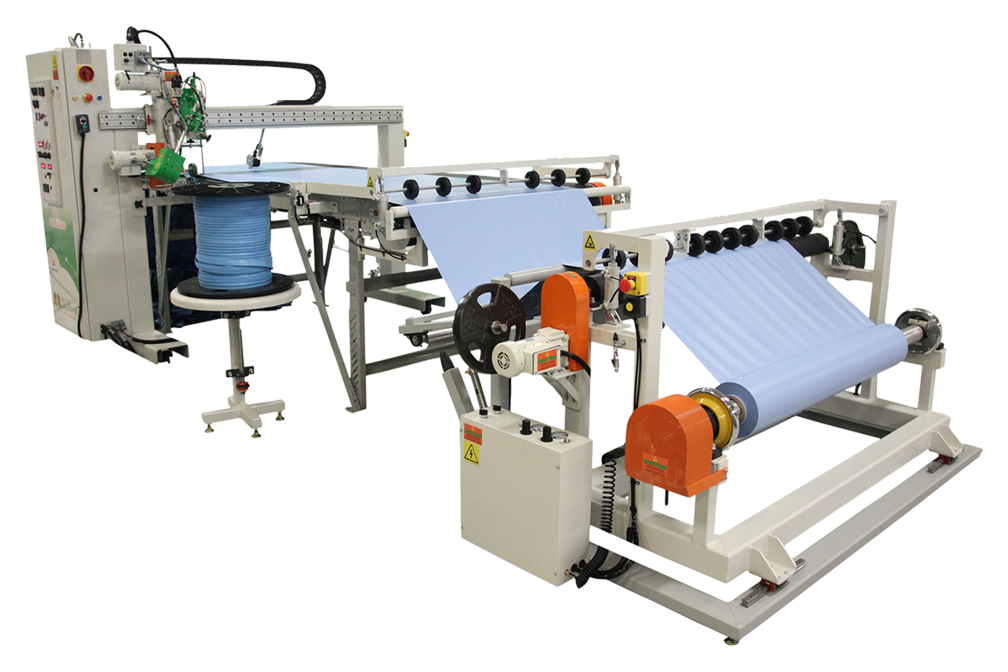

Whether you're in the business of manufacturing tensile structures, pool liners, high-speed rolling doors, oil booms, or billboards, our fabric welding machines are designed to handle a broad array of applications. With their ability to create strong and airtight seams, our machines stand as the preferred choice in the textile industry.

Furthermore, our fabric welding machines offer considerable adaptability. They can handle a range of materials, including but not limited to PVC and polyurethanes. Our RF fabric welding machines can even weld the same area more than once without damaging the fabric.

If you're unsure of which fabric welding machine to choose for your application, our team at Miller Weldmaster is here to assist. We'll help you select the best technology that aligns with your specific application, ensuring optimal results every time.

Explore our complete range of fabric welding machines. Make the smart choice and invest in a fabric welding machine from Miller Weldmaster today, for precision, efficiency, and cost-effectiveness.