Trust Miller Weldmaster to get your started!

STEP ONE

Schedule Your Training

A Miller Weldmaster certified field service engineer will contact you to schedule installation and training at your facility.

STEP TWO

Installation Preparation

We provide you with everything you need to know to get your team ready for installation and training.

STEP THREE

Staff Training

Your staff will receive extensive instruction on welding equipment operation and maintenance and how to produce your product.

Flat Seam Tube

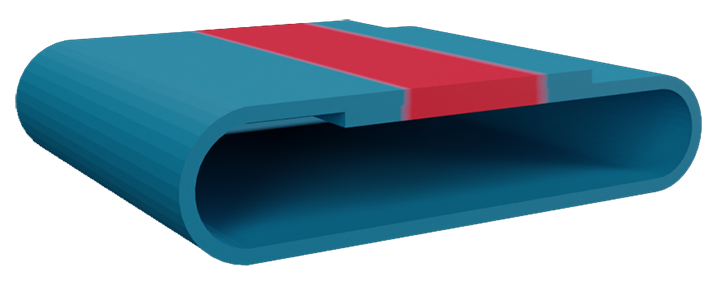

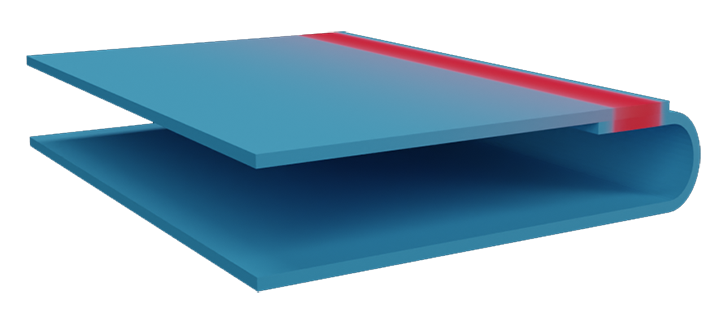

Flat Seam Tube  Fold Overlap

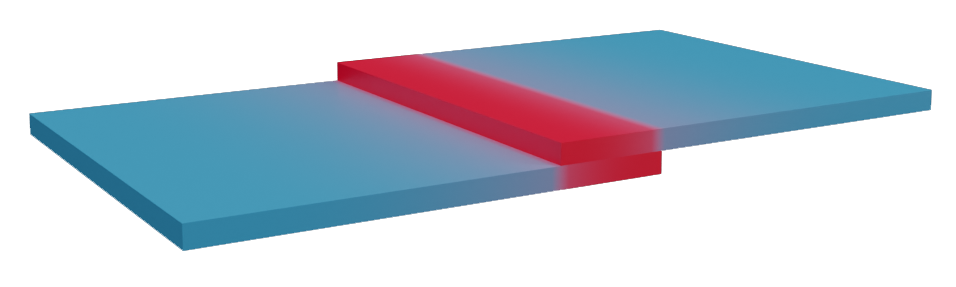

Fold Overlap  Overlap

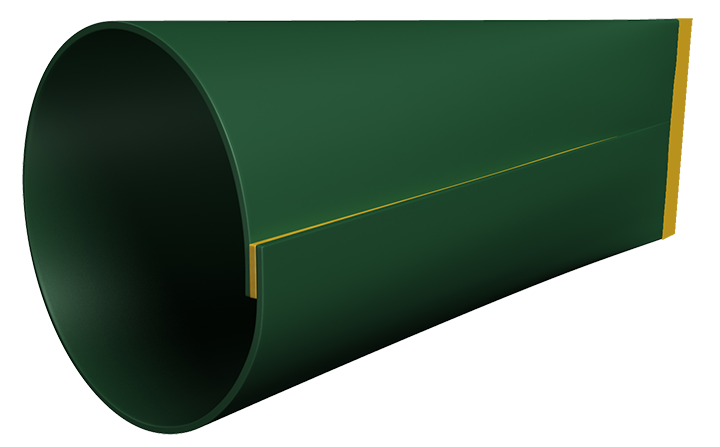

Overlap  Tube

Tube